Galvanized Hog Rings Versus Pinning Nails

There are two types of anvils used on impact wrenches: galvanized hog rings and detent pins (sometimes called pinning nails). This article will describe both types of anvils, how they work, and which type is better for certain applications.

Let’s start first with hog rings.

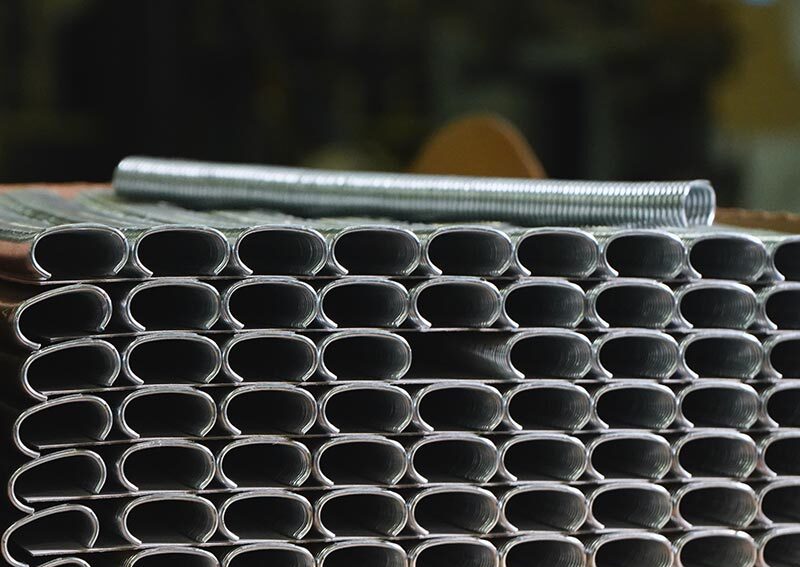

Hog Rings (Friction Rings)

Also called “friction rings,” galvanized hog rings are metal rods that are typically manufactured in the shape of the letter “C”, although there are also D-type hog rings. Open-ended, standard C-type hog rings can be compressed closer to an “O” shape into a groove on the square side of the anvil.

The exterior circumference of most hog rings (on the end of the anvil) is slightly larger than the interior circumference of the socket’s connection end. This yields a frictional force.

The hog ring compresses as the socket is snapped over the anvil, and then expands once the socket is firmly placed. The internal friction created by the hog ring’s expansion is what holds the socket on the impact wrench’s anvil.

Pinning Nails (Detent Pins)

In mechanics, a “detent” is any lock that prevents motion until it is intentionally released. Impact wrenches can also use detent pins, or pinning nails. A detent anvil uses a retaining pin that has to be depressed in order to remove a socket from an impact wrench. This type of connection typically requires depressing the pin with a small tool while prying the socket loose.

Which Is Best?

The most simple answer is this: galvanized hog rings are best for most applications because they are more versatile and easier to use. Impact wrenches with hog ring anvils are the preferred choice of many automotive mechanics and home-based machinery shop operators because they allow quick changing of sockets, while still providing a strong socket-to-wrench connection.

However, the best choice between hog rings and pinning nails comes down to personal preferences and the application that the impact wrench is being used for.

Detent Pin Applications

Detent pin anvils make it more difficult for a socket to come off. This type of connection can be useful for applications where a same-sized socket will be used repetitively.

Common applications for detent pin impact wrenches include:

- Erecting Steel Buildings

- Water Tower Assembly

- Bridge Building

Detent pin wrenches are also useful for high-altitude applications where you would not want a socket to come off the wrench unexpectedly, possibly causing injury to someone below.

Galvanized Hog Ring Applications

Galvanized hog rings are perfect for lower-altitude impact wrench applications where you need to frequently switch between different sockets. Hog ring anvils allow for easier manual removal and replacement of sockets without using pin-depressing or prying tools.

Find Galvanized Hog Rings from King Steel Fasteners

Do you need help choosing the right anvil type for your impact wrench? Get in touch with our team at King Steel Fasteners. Based in Oxford, MI, we’re a family-owned and -operated supplier of integrated fastening systems. We proudly offer galvanized hog rings, staples, and other high-quality American-made products to clients around the world.

To learn more about our products, visit our online shop, or you can fill out our online form today to speak with one of our experts.