Selecting the Right Fasteners & Tools

Selecting fasteners, like hog rings and clinch clips, is serious business. You have to consider more than just the cost because using the wrong type of fastener can result in complete project failure.

Read on to learn how to select the best fasteners for your projects and the best tools for them.

Selecting Fastener Type

If you want your finished product to last long and perform well, size and material type are the two most important considerations.

Think about the environmental conditions the fasteners will be exposed to, like extreme temperatures, water, high humidity, or coastal areas with salty atmospheres. Also, consider if the fastener will be subject to heavy shock, pressure, or vibration.

The two primary types of fasteners you may have to choose between are hog rings and clinch clips.

Hog Rings Versus Clinch Clips

Hog rings and clinch clips share common applications, including:

- Attaching automobile upholstery to metal framing

- Connecting labels to manufactured products

- Securing chain link fencing & razor wire

- Building animal cages & traps

Despite their common applications, they do have some differences.

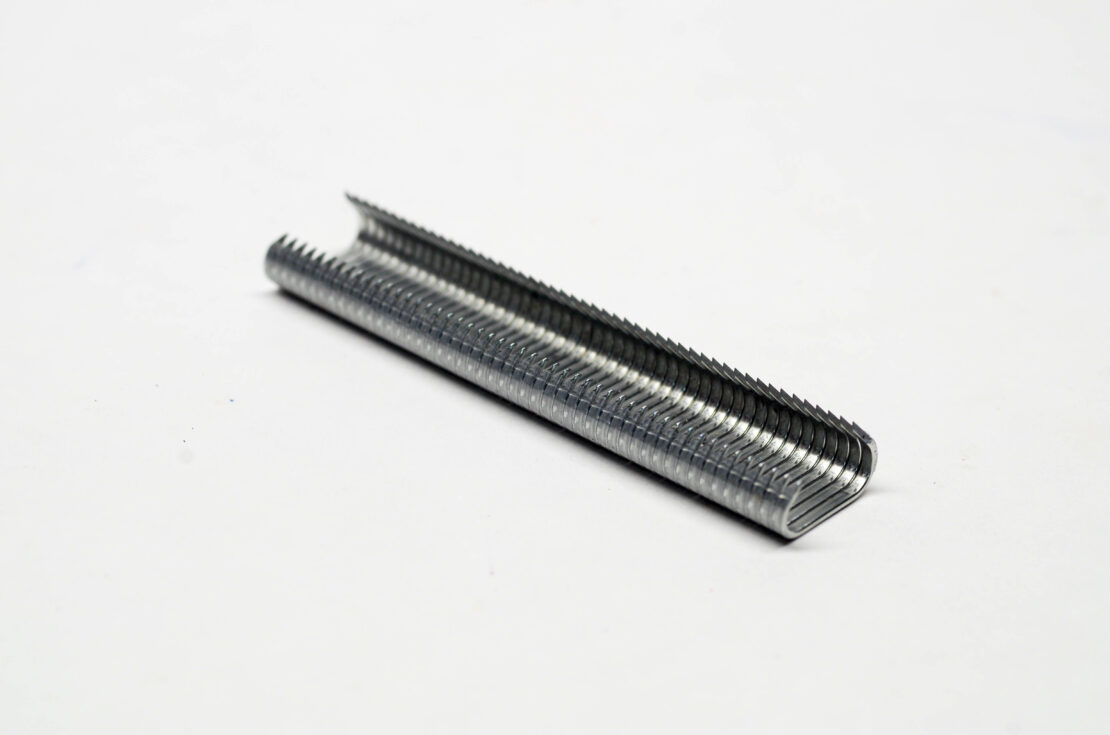

First, hog rings are C-shaped and D-shaped industrial-strength staples and are available with pointed and blunt ends to match the application at hand, while clinch clips are flat rectangular fasteners.

Beyond their general shapes, the primary difference between the two is that hog rings are much simpler to remove if needed and can be repurposed. Removing clinch clips is difficult at best, and they’re not suitable for effective reuse.

Choosing a Material

Materials matter when selecting clinch clips and hog rings. The most common materials used to manufacture them are aluminum, galvanized steel, and stainless steel.

Aluminum

Aluminum is a low-cost option. It’s also lightweight, non-magnetic, and a good electricity conductor. And because it doesn’t rust, aluminum is better than some types of steel for use in marine environments. Aluminum is also non-toxic, which makes it great for situations where hog rings may come in contact with food (clamping sausage casings, etc.). One downside is its high malleability (softer) makes it less durable than steel and it will wear out faster in high-friction environments.

Galvanized Steel

Steel that’s hot-dipped in a galvanizing coat (typically zinc) resists corrosion for a long time, even in coastal areas. However, the thick coating makes the fasteners less compatible with other materials, and if the coating itself is damaged, it can cause galvanic corrosion, which will rapidly degrade the material.

Stainless Steel

Stainless steel is a popular material for making hog rings and clinch clips because of its superior durability and strength. It’s also excellent for use in corrosive environments because it contains chromium, which makes it naturally resistant to corrosion and rust. The only downside is that stainless steel fasteners are generally more expensive than fasteners made with aluminum or galvanized steel.

Selecting Size

Hog rings are available in 0.25-, 0.375-, 0.5-, 0.75-, and one-inch sizes, denoting the distance between the two endpoints before use. It’s important to choose the correct size for the project at hand. It’s common to choose oversized hog rings, but doing so makes it more difficult to tighten them properly, and increases their risk of failure. Clinch clips are also available in multiple sizes, including different lengths, internal crown widths, and height. Like hog rings, choosing the correct clinch clip size is crucial for a project’s long-term success.

Selecting the Right Tool

First, if you’re selecting a hog ring, you need a specialized hog ring gun, and if you’re choosing a clinch clip, you’ll need a clinch clip tool.

Both hog ring and clinch clip tools are similar to staple guns because they hold entire strips of hog rings or clinch clips at a time that are automatically fed into the jaws as you work. It’s also important to note that different clinch clip and hog ring tools will operate differently and may only operate using specific types and sizes of clinch clips and hog rings, so be sure you pick the correct tool for the type and size of fastener you’re using.

If you only have a few hog rings or clinch clips to install, you can get by well enough using a pair of manual pliers. However, if you need to install numerous fasteners, you can save time and money by using an electric or pneumatic hog ring gun or clinching tool.

Manual hog ring and clinch clip tools are less expensive than electric and pneumatic options and are easier to maintain. However, they can’t match the speed and efficiency of their electric and pneumatic counterparts. Electric tools cost less than pneumatic versions, plus a pneumatic tool is bulkier, requires more maintenance, and can be a bit tricky for some users to learn to operate.

- Manual Hog Ring Gun & Clinching Tools: Less expensive than electric and better suited for small jobs as they can cause hand fatigue when used for larger jobs.

- Electric Hog Ring Gun & Clinching Tools: Fast, efficient, less expensive than pneumatic guns, and ideal for large jobs.

- Pneumatic Hog Ring Guns & Clinching Tools: Bulky, more maintenance, difficult to use, but fast and efficient for large jobs.

Purchase Fasteners & Tools From King Steel Fasteners Today!

Founded in 1995, King Steel Fasteners is a trusted supplier of high-quality, American-made fasteners and tools. If you need help selecting the right fastener, don’t hesitate to contact us. We’re here to help!